Industry 4.0 at L'Oréal: The beauty industry is gaining momentum

Digital technology is accelerating our relationship with the world and changing our consumers’ attitudes. In order to thrive in this era of “fast beauty,” we’re constantly reinventing our supply chain and how we operate. Here’s an overview of the innovations we’ve created for our clients.

The new rules of the game

“Our consumers have evolved more in the past 3 years than in the 30 years prior,” explained Stéphane Lannuzel head of management for the transformative product Beauty Tech at the Vivatech salon last May. The sentiment was echoed by Cristina Monnoyeur, director of digital transformation in operations, “They’re much more concerned about the environment, they want more transparency and they want access to everything, all the time, everywhere.” With these changes in mind, we decided to invest in Industry 4.0: a new type of industry that harnesses every new industrial technology in product development, manufacturing, and production lines.

Our mission: to be more agile, more efficient and advance even faster— especially on reducing the time to market of our products.

Our packaging centers have already adopted 3D printing and VR thanks to Anne Debauge, head of packaging and operation development 4.0. These innovative technologies allow us to rapidly model future products by internalizing the manufacturing process of prototypes and indispensable production tools. Previously considered one of the longest phases, today rapid prototyping only takes 24 hours. Thanks to this process, 14,000 prototypes were made in 2018 alone!

One word: agility

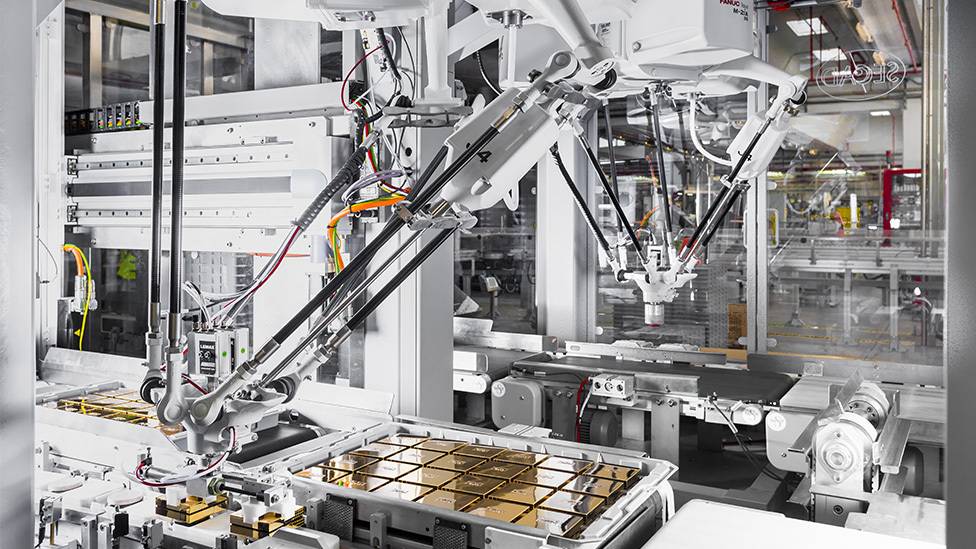

To go from mass production to exclusive production while playing with the format, color or label of the product necessitates flexibility and agility. In order to rise to this challenge, we digitized our production tools. Our Lassigny factory, a pioneer of Industry 4.0 at L’Oréal, points to the direction we’ve taken with its cutting-edge technologies, artificial intelligence and digital tools. Intelligent sensors, touchpads and even cobots (collaborative robots) assist and simplify the everyday work of the site’s operators.

In parallel, we’re developing more and more connected products. They improve the traceability of our articles and create more transparency for customers. Thanks to RFID technology, we’re making our customers’ journey and in-store experience as fluid as possible. The RFID chip is already found in stores with our NYX products.

The art of tailor-made solutions

To respond as precisely as possible to our clients’ demands, we’re developing more and more personalized products. Certain retailers now offer engraved messages on perfume bottles or let clients participate in making their own foundation, satisfying a growing demand for “co-creation.” With My Little Factory, our factory of the future presented at Vivatech, we’re hoping to offer large-scale customization.

This digital transformation is spurring our company down a path of excellence. It’s a disruptive, agile and innovative approach to serving our customers.

To find out more about Industry 4.0 at L’Oréal

Discover our special report, “Operations,” and read our article “How The Beauty Industry is Transforming with Technological Innovation.”